Near-paranoid process requirements and manufacturing standards

Stringent anti-aging test

Our first-class testing laboratory conducts stringent tests in respect of UV aging, high-temperature, acid-alkali resistance, sharpness and the like on products, so as to ensure the high quality of each batch of products.In respect of various factors involved in the actual conditions of use, the experiments on the condition of aging of the product are strengthened.

1,000-stage Clean Dust-free Workshop

The selection of the air filters with different levels of air cleanliness for the 1,000-stage clean dust-free workshop at constant temperature, constant humidity and dust-free control, minimizes foreign particles and maximizes the purity of window films, ensuring batch production, stable quality and rapid supply.

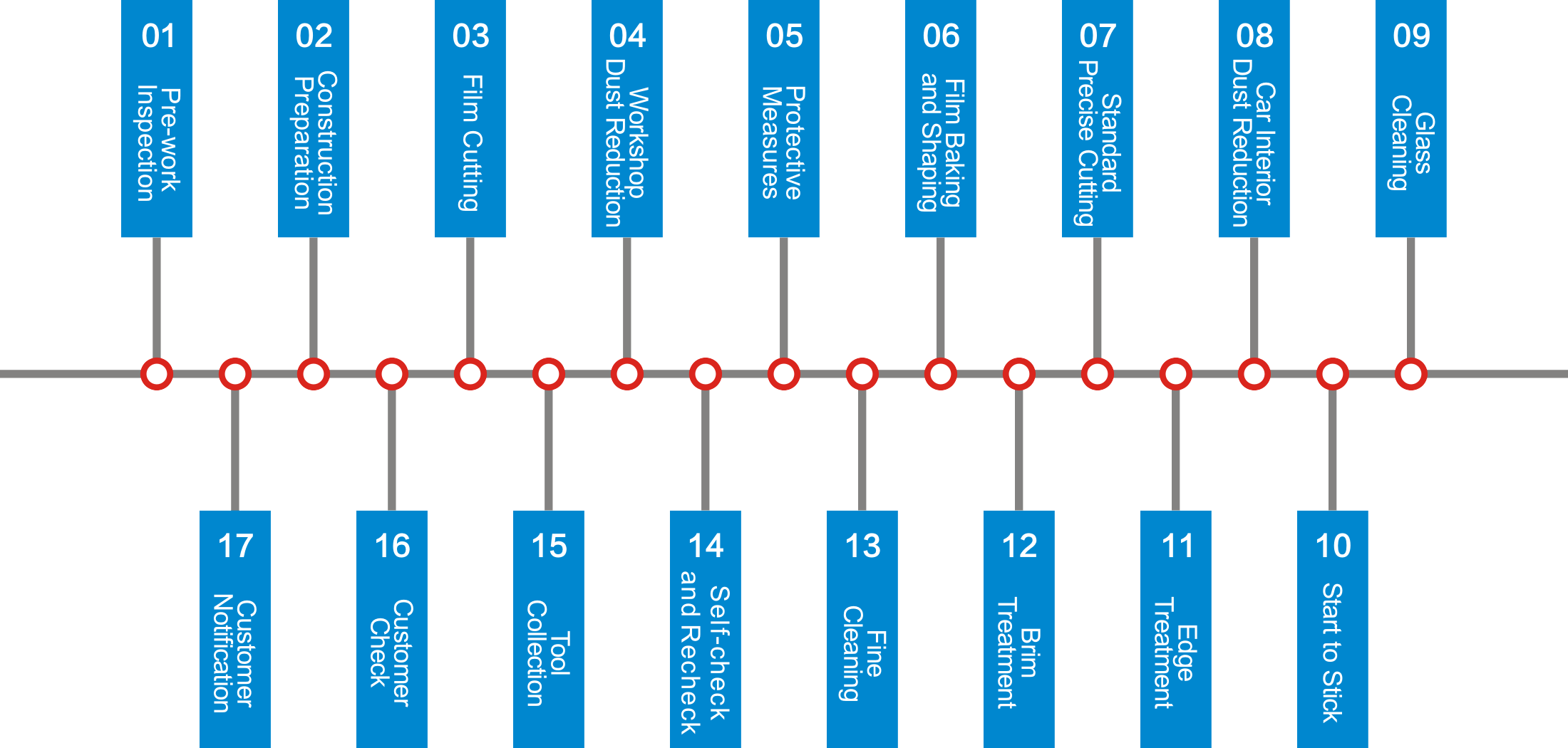

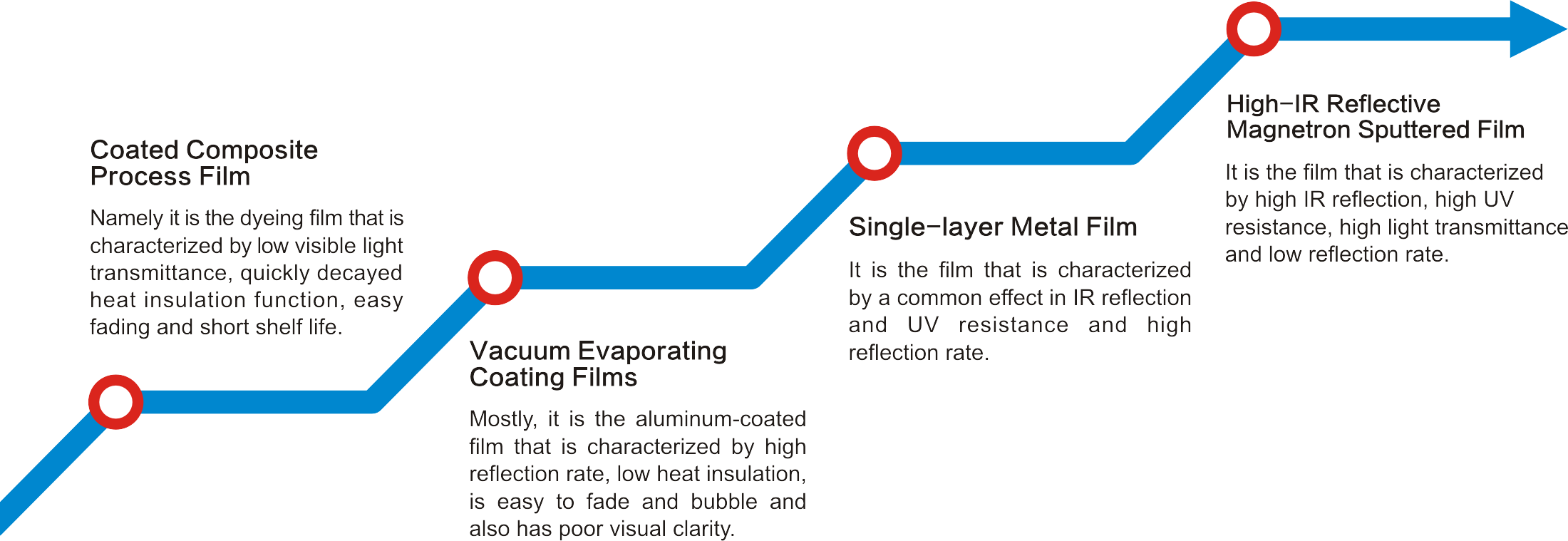

Development Process of Window Film Technology

The standard construction process of the 17 steps brings the perfect presentation of XMFAN window films.

The film sticking tools special for XMFAN films, from the blade, the pad, the small scraper to the special-shaped extension scraper and the lengthened cast aluminum handle, etc., all are imported from the USA, standard and easy to use, and truly indicate the professionalism of XMFAN films. The special neutral cleaning solution and mounting solution for XMFAN film are more professional, more convenient and more environment-friendly in order to make every film sticking process perfect.